Know Your Materials

First, an understanding of the characteristics of different metals is crucial. Every material behaves in its own way when subjected to stress, and they all have their own peculiarities when it comes to machining. Take aluminium for instance, which is a flexible, machinable material with a high strength-to-weight ratio, meaning it is a suitable metal for the aerospace sector where the weight of the component is crucial. Stainless steel, on the other hand, is preferred because of its corrosion resistance, which is important when you are talking about medical devices. The choice of material does more than just affect how the prototype behaves: it also influences manufacturability.

Design for Manufacturablity (DFM) as a Strategic Driver

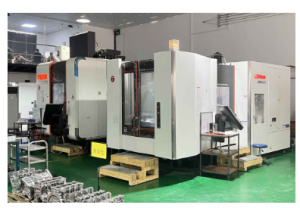

DFM uses knowledge based upon the lessons learned during the design, tooling, preparation, build and support phase of the life cycle of similar products built and supported by the same ESU to give specific design criteria as to which designs are preferred, if manufacturing processes are to be efficient. Designers can reduce complicated operations and the rate of scrap materials along with low manufacturing costs with the help of DFM principles. Let me give you a for-instance: CNC machining plus a reduction part orientations will allow you to cut down setup times by approximately 50% and overall production time by almost 30%.

Integrate Advanced CAD Tools

Design optimization for custom metal prototypes Fabrication cannot be done without computer-aided design (CAD) tools. That lets designers render detailed 3D models that accurately portray the physical properties of the finished product. Modern CAD software is able to predict where the major stress lines will form and what failure modes may result in these areas, giving engineers the ability to fix these design flaws without even entering the prototyping phase. Not only does it save time, but it makes sure the prototype is as dimensionally accurate to the design intent as it could be.

To Simplify Is to Amplify

Another good approach is to keep the the design as simple as possible. Although this does not imply a lower quality or functionality part, it is more about reducing unnecessary complexities that may make fabrication difficult. One such example is reducing the number of tight tolerance requirements and where not critical to the design in areas can lead to large reductions in machining time and cost.

Opt for Modular Design

This can make a product much more flexible and scalable by design. This method includes to make individual pieces which directly attach others for making a fully function able system. Having modular packages is crucial for future-proofing the solution, allowing individual parts to be replaced/bulk and expensive parts to be upgraded separately from the full prototype, extending the prototype's lifetime and adaptability.

Focus on Iterative Testing

Iterative testingBecause of the variety between types of metal and methods of production, testing is a critical part of refining designs for metal prototyping. Testing the prototype early and often, provides a steady stream of feedback that can be used to improve the design. This iteration will enhance the prototype accuracy and minimize the reappearance of modifications that would be costly during mass production. One study found that using iterative testing decreased development costs by 25%, as well as helping catch design flaws early on.

Drive Collaboration Between Disciplines

Facilitating a team-working ethos between design, engineering and manufacturing, aids in creating more innovative and practical design solutions. By involving all stakeholders during the design phase, it is possible to catch potential problems faster that would have otherwise slowed down the prototyping. Through effective collaboration, the end product (often) is not only polished but also aligns to most of the functional and budgetary constraints.

Through the careful crafting of a prototype, talented designers and engineers, contending with the available resources, know very well how to streamline and optimize design process for custom metal prototype fabrication to guarantee each prototype not only working and cost-effective but also ready to be mass-produced.